The Effect of Diaper Biodegradability on Absorbency

ABSTRACT

A typical disposable diaper takes 500 years to decompose, leaving toxins in the environment. The main layer of a diaper, the absorbent core, is usually made out of wood pulp and a plastic super absorbent polymer, even in diapers labeled biodegradable. We wish to identify how performant, eco-friendly, and affordable disposable diapers are. Therefore, we chose our diapers on various scales of biodegradability, depending on their plant-based components. To understand the different aspects of absorbency, we adapted a typical set of diaper tests [1]: DM, FSC, TAC, AUL, LST, FRO, MC, and implemented them on our diapers. The most popular diaper, made of mostly plastic, performed the worst. It had a TAC of 1110.96wt% in saline solution and a density of 0.01g/. Biodegradable diapers outperformed their long-degrading plastic counterparts. These experiments proved that being biodegradable does not diminish a diaper’s performance, but rather, improves it.

INTRODUCTION.

Diapers were originally made with natural materials, such as moss, before evolving into cloth diapers using woven textiles. After people found that soiled diapers caused sickness and ruined clothing, disposable diapers were introduced as they were easily discarded and prevented rashes [2, 3]. Overtime, people discovered that the plastic in disposable diapers hurt the environment, especially as they can take up to 500 years to decompose, so some companies started creating eco-friendly diapers [4].

Diapers have been established as an extremely important necessity in the lives of babies and their families. Disposable diapers have made it much easier for parents to conveniently change diapers and dispose of them by saving both time and effort. However, their expensive price has made it difficult for many of these families to afford as some low-income families have to choose between food and diapers. A research study which surveyed 877 pregnant and parenting women collectively showed that 30% of the mothers expressed diaper need [6]. Diapers are a luxury item and biodegradable diapers even more so.

A super absorbent polymer (SAP) is a gel-based material that can hold water, the main functional component of a diaper. Beyond the SAP, five other elements are incorporated in the physical disposable diaper: the topsheet, acquisition distribution layer (ADL), absorbent core, backsheet, and adhesives used to hold all of the layers together (Fig. S1).

The topmost layer of the diaper is the topsheet. It is the layer of the diaper that directly touches the baby’s skin. The topsheet is most commonly created by hydrophilic and hydrophobic polymer-based nonwovens that help to quickly absorb the urine and at the same time be moisture repellent at the surface. Some natural diaper brands use bamboo fibers instead to achieve this purpose. After the topsheet absorbs the urine, it spreads to the ADL. Its function is to evenly distribute the urine throughout the diaper before ultimately reaching the absorbent core. The absorbent core’s primary purpose is to effectively absorb all of the urine without allowing it to seep out, even when pressure is applied. It is often made using cellulose fluff pulp and superabsorbent polymers (SAP). These materials skillfully help the diaper retain all the liquid. The backsheet is the outermost layer of the diaper and holds everything inside the diaper. The layer is most commonly made out of polypropylene nonwovens. This material is an inexpensive choice and hard to replace due to its protective yet breathable nature. Non-plastic-based nonwovens are used in more biodegradable and eco-friendly diapers. Although it is more expensive than plastic, it is more beneficial for the environment while still being effective. Adhesives are another very important component in any diaper. They help to place and adjust the diaper to properly fit the baby and attach the different layers of the diaper. These adhesives are typically made of plastic in diapers, even in eco-friendly ones. The most common adhesives used are PLA (polylactic acid), a non-woven fabric, and PCL (polycaprolactone), a biodegradable polymer [5].

Very few researchers have investigated the relationship between the environmental impact of disposable diapers to the performance of various commercial brands of baby diapers, both plastic-based and biodegradable. In this study, we compared and assessed the adsorptive and biodegradable properties of disposable baby diapers and their superabsorbent polymers. For the purpose of ethics and respect, we maintained the anonymity of the companies and excluded their trademarks in this study.

MATERIALS AND METHODS

Each test is adapted from methods by Bachra et al [1]. Here, we used the same industry standard methods to evaluate the performance of both plastic and biodegradable diapers. For every experiment involving liquid, a 1% saline solution was used to replicate urine and each test was run in triplicate. We tested 5 diapers in order of increasing biodegradability with Diaper A as least biodegradable and Diaper E as most biodegradable. When discussing biodegradability, we do not mean fully biodegradable, but rather market biodegradable. Biodegradability is a spectrum. This is mainly because there are not any fully biodegradable SAPs that can be accessed commercially. Biodegradability was based on the percentage of parts that were biodegradable. Due to outside limitations Diapers A, B, and C were infant fit size two, Diaper D was size five, and Diaper E was size three. Most experiments tested a uniformly-sized subsection of each diaper, so the different infant sizes did not impact the results.

Dimensional Measurements.

The Dimensional Measurement (DM) test calculated the density of the SAP distribution. The length and width were measured using a ruler. Approximately 1.5 cm from the edge of the diaper three circles (diameter 1cm) were drawn with a pen, one circle at the front, back, and in the center. The caliper was centered in each circle to measure the thickness. The weight of the diaper was also measured before using Eq. 1 to find the density.

\[Density\left(\frac{g}{cm^3}\right)=\frac{Mass(g)}{Length\left(cm\right)\ast Width\left(cm\right)\ast Thickness(cm)} \tag{1}\]

Absorption Under Load.

The Absorption Under Load (AUL) test was used to simulate a baby sitting on a full diaper. We designed a 3-D printed apparatus to store a weight of 0.3psi that applied pressure to the SAP which rested on a mesh grid. We recorded the weight of the apparatus with SAP as W1 [1]. We then placed the apparatus with SAP onto a liquid-filled petri dish so the SAP under load could absorb fluid through the mesh grid (Fig. S3). After an hour of fluid absorption, the SAP in the apparatus was reweighed as W2.

\[AUL\ 0.3psi\ \left(\frac{g}{g}\right)=\ \frac{W_2-W_1}{W_1}\tag{2}\]

Free Swell Capacity.

The Free Swell Capacity (FSC) test finds out how much liquid the SAP can hold without any weight placed on top. We measured how much liquid was absorbed by SAP stored in a tea bag. Fa represents the absorption factor of the teabag, T2 represents the weight of the empty strained teabag, and T1 represents the weight of the dry empty teabag. W2 represents the weight of the swollen sample, W1 represents the weight of the dry empty teabag, W0 represents the original weight of the SAP sample.

\[F_a\left(\frac{g}{g}\right)=\frac{T_2-T_1}{T_1}\tag{3}\]

\[FSC\left(\frac{g}{g}\right)=\frac{W_2-{\left(W_1-F_a\right)-W}_1-W_0}{W_0}\tag{4}\]

Fluid Runoff.

The Fluid Runoff (FRO) test determines the rate of absorption by the topsheet if the liquid falls with no real force. A volume of 25 mL of liquid was dropped on a diaper over the course of 3 trials without replacement. Each trial lasted 10 minutes, the weight of unabsorbed liquid was recorded at the end of each trial.

Liquid Strike-through.

The Liquid Strike-through (LST) test evaluates how fast the liquid can go through the topsheet with a force simulating urine behind it. We dropped a drop of saline solution on the slanted diaper and recorded time to dry.

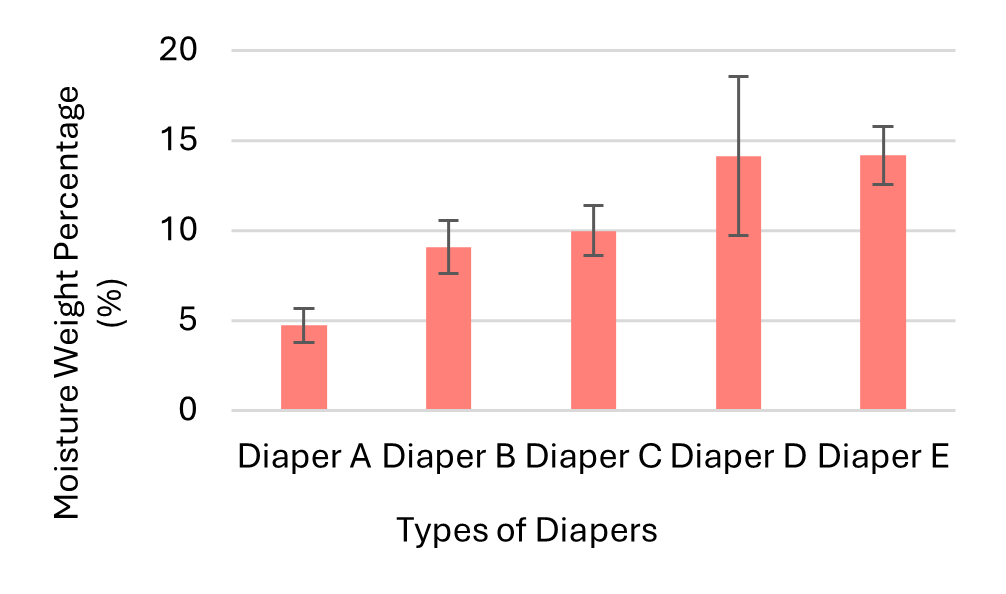

Moisture Content.

The Moisture Content (MC) test was used to examine how much moisture was already in the SAP from the humidity of the factory it was made in. The optimal range for moisture content of an SAP is 5-15%. We weighed covered glass dishes (M1) after heating and first round in a desiccator. 4 g of SAP was added to dishes and reweighed (M2). Next, uncovered dishes baked in an oven for 3 hours then in desiccator for 30 minutes. Finally, the covered dishes were reweighed (M3).

\[MC(\%)=\frac{M_3-M_2}{M_2-M_1}\ast100 \tag{5}\]

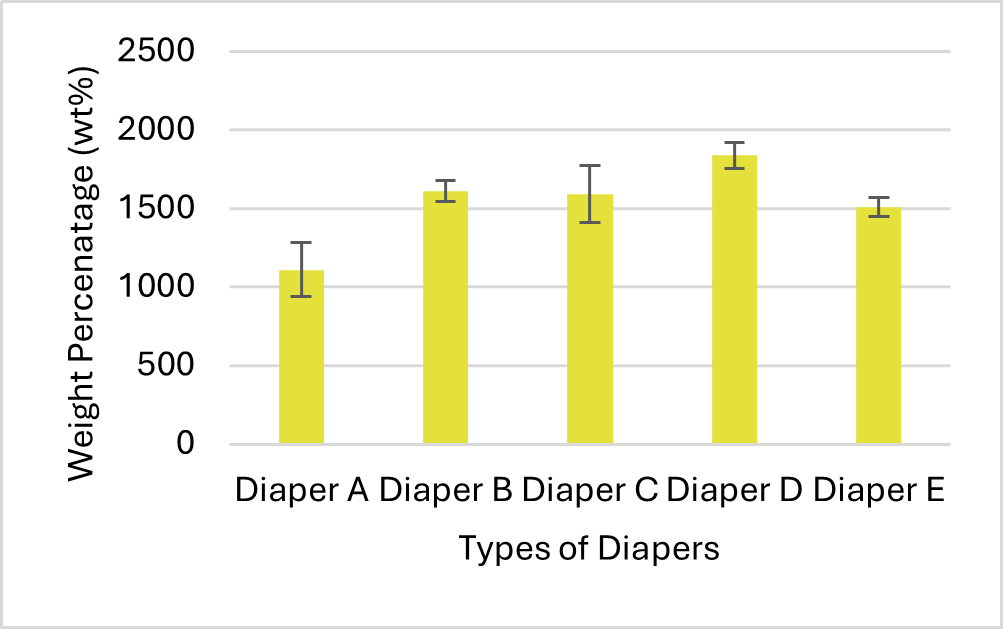

Total Absorptive Capacity.

The Total Absorptive Capacity (TAC) test was used to find out how much liquid the whole diaper could hold. The diaper’s dry weight was W1. The diaper was completely submerged in saline solution for 30 minutes then dried to remove excess liquid, then its final weight (W2) was recorded.

\[TAC(\%)=\frac{W_2(g)}{W_1(g)}\ast100\tag{6}\]

RESULTS.

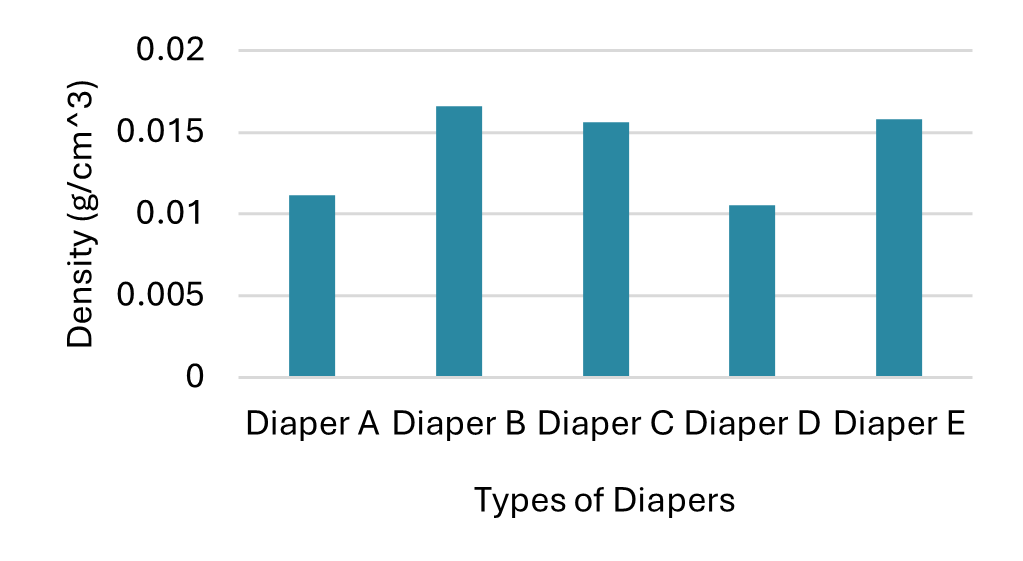

Dimensional Measurements.

Our five diapers were all different infant sizes due to outside limitations. This affected the length, width, mass, and density. However, based on Fig. 1, all of the diaper’s widths regardless of size were very similar raging from 9-9.5 cm.

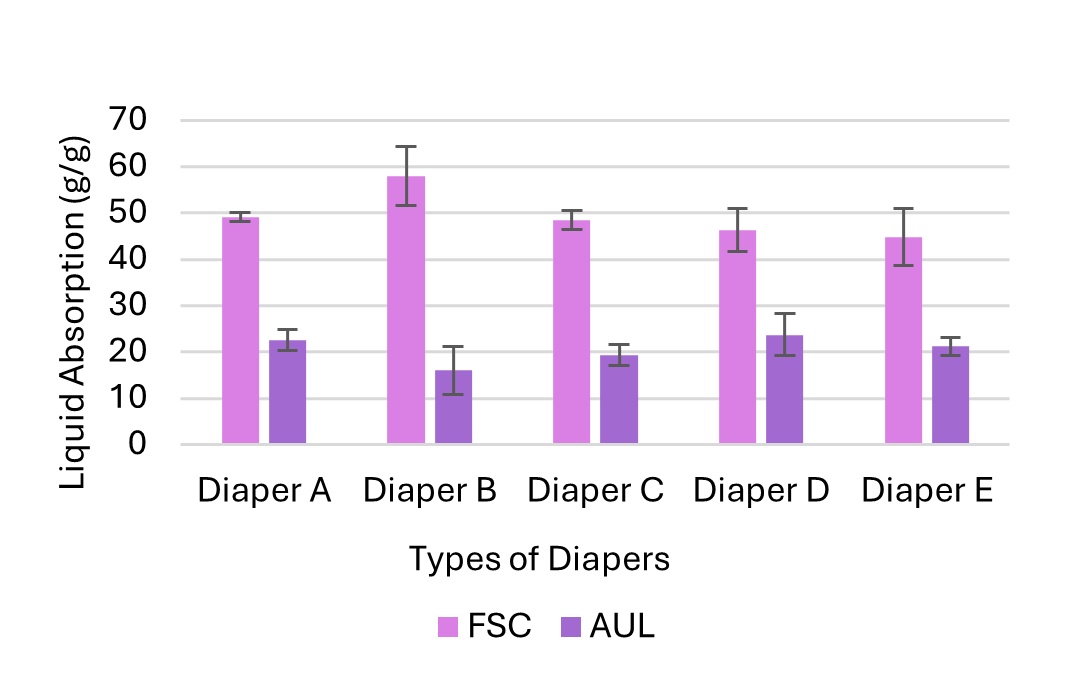

Absorption Under Load and Free Swell Capacity.

According to Fig. 2, AUL values stayed around 20 g/g with no trend to biodegradability. FSC values were much higher than AUL values, with no clear trend of absorbency.

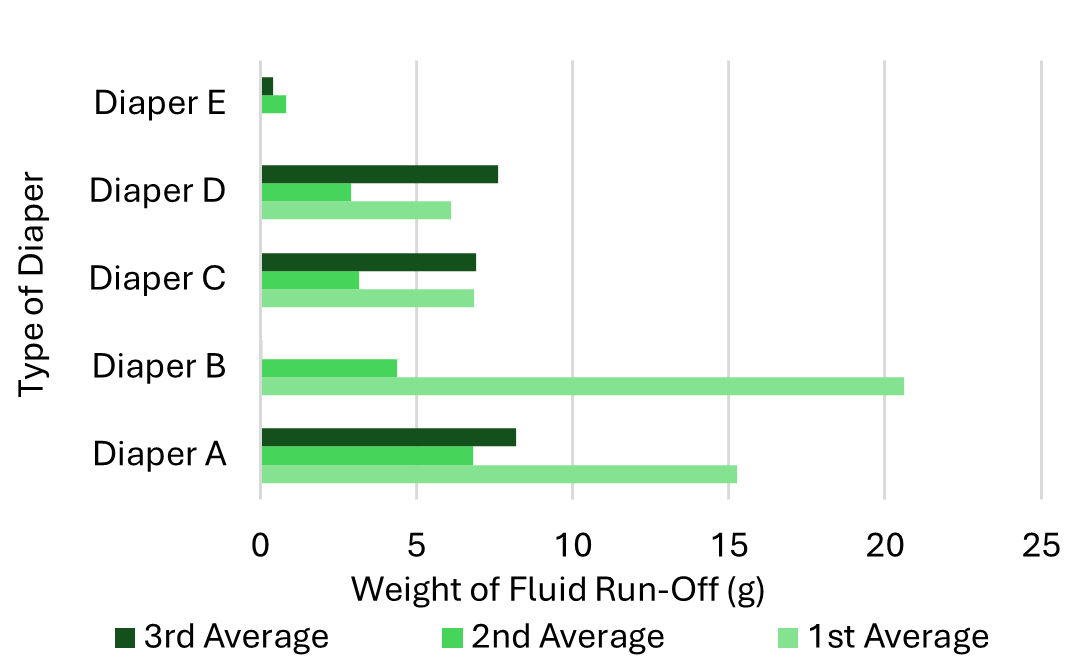

Fluid Runoff.

For the fluid runoff test, we recorded the mass of the unabsorbed solution. Larger mass volumes indicate less absorption. Diaper E had the lowest absorption mass all three times with weights of 0, 0.83, 0.41g (Fig. 3). Diaper B had the most fluid runoff after the tertiary section, with weights of 20.62, 4.38, 0.07g. Diaper A had the most fluid runoff in the primary and secondary sections, with weights of 15.26 and 6.82 g.

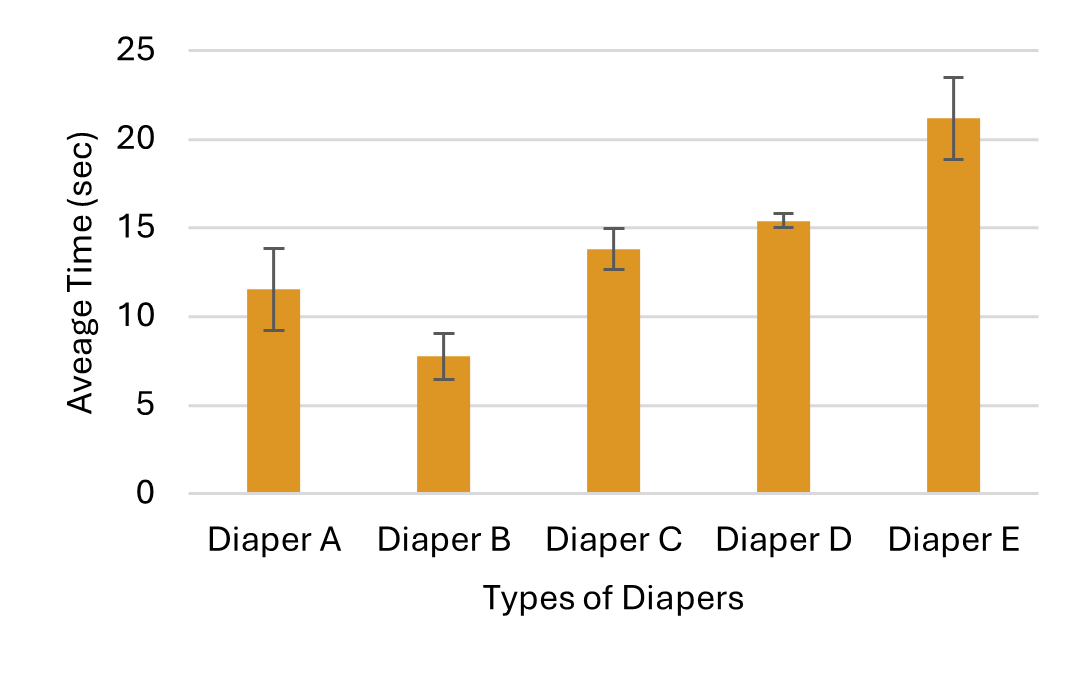

Liquid Strike-through.

Diaper B had the lowest average time for absorption at 7.73 seconds. Diaper E had the slowest time experiment at 21 seconds (Fig. 4). Excluding Diaper A, the absorption time trended upwards with increasing biodegradability.

Moisture Content.

Typical moisture values should be between 5-15% for an SAP to absorb at optimal efficiency [7]. The results were varied for all the diapers, though Diaper E and Diaper D were quite close with 14.17% and 14.16%, respectively (Fig. 5). Diaper A was below the optimal range at 4.7%.

Total Absorptive Capacity.

According to Fig. 6, Diaper D had the highest total absorption capacity percentage at 1839% though this could be due to its size, as it is a size five diaper and probably holds more SAP. Diaper B had the highest total absorptive capacity percentage among the three diapers that are size 2 at 1612%. Diaper A had the lowest total absorptive capacity for all of the diapers at 1111%.

DISCUSSION.

Dimensional Measurements.

Since the diapers mostly varied in infant size, the dimensional measurement testing had no trend depending on the spectrum of biodegradability. However, the different dimensions did not impact many of our tests since they evaluated a uniformly sized sub-section of the diaper. The thickness of Diaper C was the lowest and was dependent on the amount and thickness of the individual layers in the diaper which could ultimately affect its absorbency.

Absorption Under Load and Free Swell Capacity

There was no clear relationship between FSC and AUL. However, it is not due to biodegradability since all the diapers used plastic-based SAP, meaning only the quality of SAP, the amount used, and the type of plastic in SAP could have affected the results. Thus, it is expected that regardless of the diaper type, biodegradable and non-biodegradable diapers had similar performance on these tests. In the future, we would like to examine a biodegradable SAP, but most are currently proprietary products not on the market.

Fluid Runoff.

The fluid runoff performance of the five diapers we tested ranged from best to worst in the order of most biodegradable to least biodegradable. Diaper E performed the best with the fastest absorbency rate every time, most likely due to its bamboo nonwoven topsheet. Diaper A, which performed the worst in the primary and secondary sections, was created with plastic and a thin layer of lotion. It was unexpected that Diaper B had such disparate results compared to Diapers C and D because they all have cotton topsheets. This discrepancy could be due to the use of different topsheet lotion brands used because Diaper B had a more hydrophobic cover.

Liquid Strike-through.

It was unexpected for Diaper E, which did the best in the fluid runoff test, to do the worst in the liquid strike-through test. Conversely, Diaper B was one of the worst in the fluid runoff test but did the best in the liquid strike-through test. The amazing performance of Diaper B could be because the top sheet and acquisition distribution layer of the diaper are both made of 100% cotton while the other diapers are either 100% polypropylene or plant-based. The different topsheet materials and lotion probably affect how fast the diaper can absorb the liquid. The inverse test performances could be based on the manufacturer’s prioritization of performance for the Fluid Runoff test rather than Liquid Strike-through or vice versa when testing the topsheet.

Moisture Content.

Based on the humidity in an area, the SAP absorbs a certain amount of moisture from the air. Since these companies have many factories all around the world, the box of diapers that we received could have had much more moisture than another box from the same company. Diapers D and E were close to 15% and A was below 5%, while Diapers B and C had more desirable results toward the middle of the ideal range, 5%-15% [7]. The results of these diapers varied a lot with biodegradability and there was therefore no clear trend of the relationship of biodegradability to absorbency. All the diapers also had neutral pH indicating the moisture content did not impact out-of-the-box SAP quality (Fig. S2).

Total Absorptive Capacity.

Diaper A had the lowest absorption, which could be due to its solely polypropylene-based structures, as all other diapers that had high total absorptive capacities were bio-based. All the bio-based diapers with mostly cotton composition, Diapers B, C, and D, had much higher absorption than Diaper E with a mostly bamboo-based composition, so cotton could hold much more liquid than either plastic or bamboo.

CONCLUSION.

Among the five diapers we tested, Diaper A is one of the most in-demand diaper brands with a unit cost of $0.37, but its performance was brought down by its plastic components (Table S1.). Diaper E is a popular environmentally-friendly diaper choice, since it is bamboo-based though it has the highest unit cost of $0.76, and Diapers B-D are much less popular cotton-based diapers with unit prices ranging from $0.43-0.55 (Table S1). Diaper A did not perform the best in any of the tests; it was average, or the worst compared to the other diapers. As such, biodegradability did not make a diaper’s absorption performance worse indicating a biodegradable diaper could be a viable alternative to non-degradable plastic diapers that harm the environment.

Future studies could run more tests to find the optimal backsheet, acquisition layer, and topsheet. Such tests could include the centrifuge retention capacity test, Fourier transform infrared spectroscopy, and the particle size distribution test, to track how well the SAP retains the liquid through the motions of the baby, what exactly makes up the SAP of each diaper, and how large the SAP pellets are, respectively.

ACKNOWLEDGMENTS.

Talya Jeter M.S., Dr. Richard Venditti, Dr. Eunkyoung Shim, Dr. Sharnia Artis, Dr. Peter Bouwma, Ecovia, Tethis, STEM-in-Action Grant, Chantilly High School

SUPPORTING INFORMATION.

The supporting information document includes layers of a diaper, table of diaper prices (prices were calculated based on brand publishing and sources cannot be disclosed for confidentiality), results of SAP pH tests, table of fluid run-off standard deviation values, all experimental quantitative data, experiment picture of AUL.

REFERENCES.

[1] Y. Bachra, A. Grouli, F. Damiri, A. Bennamara, M. Berrada, A new approach for assessing the absorption of disposable baby diapers and superabsorbent polymers: A comparative study. Results in Materials 8, 3-11 (2020).

[2] “Baby2Baby Begins Manufacturing Diapers for Families in Need.” Nonwovens Industry, 30 Sept. 2021, https://www.nonwovens-industry.com/contents/view_breaking-news/2021-09-30/baby2baby-begins-manufacturing-diapers-for-families-in-need/

[3] The History Of Diapers. Lil Baby Cakes, (n.d.), https://www.lilbabycakes.com/pages/history-of-baby-diapers.

[4] Profiles in prevention — do good diapers. Clean Water Action.(n.d.). https://cleanwater.org/profiles-prevention-do-good-diapers#:~:text=It%20takes%20up%20to%20500,generate%20one%20ton%20of%20garbage.

[5] M. Hussain, S. Maqsood Khan, M. Shafiq, N. Abbas, A review on PLA-based biodegradable materials for biomedical applications. Giant 18, 1-31 (2024).

[6] M. V. Smith, A. Kruse, A. Weir, J. Goldblum, Diaper Need and Its Impact on Child Health. Pediatrics 132, 253-259 (2013).

[7] F.J.L. Villanueva, “Soft Granular Superabsorbent and Use Thereof” (US 2012O157634A1, United States Patent Application, 2012).

Posted by buchanle on Wednesday, July 2, 2025 in May 2025.

Tags: absorption, biodegradable, disposable diaper, superabsorbent polymer